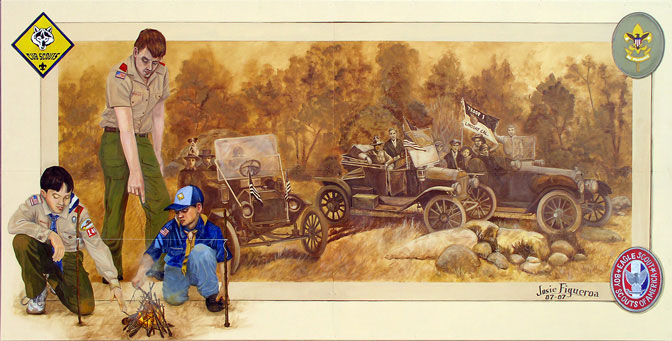

The City of Lindsay commissioned artist Josie Figueroa to paint a mural as an ode to the first Boy Scout troop in California, “Troop One.”

Robert Baden Powell created the Boy Scouts in England and 1907, bringing the idea to the east coast of America just three years later.

Articles by Collection: DIBOND®

Artist Creates Aluminum Dragonflies To Enliven Building Exterior

Although primarily used for signage and display, Dibond aluminum composite material has been featured on a global scale in several unique applications. The Regency Dragonflies of Hollingdean in Brighton are the epitome of unique.

Sliding Door System Uses Dibond ACM

One of Comhan Holland’s many indoor tensioning systems is a lightweight sliding-door frame system called T-Door.

The quick and easily assembled design has a variety of applications such as; exhibition stands, screening/separation in showrooms, warehouses, storerooms, retail displays, and other interior applications.

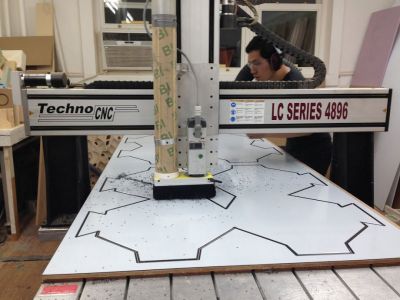

Graphic Display USA How To: Cutting Dibond

Dibond Material can be cut using various methods common to both the metal and woodworking industries. These methods include cutting with table saws, panel saws, multiple operation rip/V-grooving saws, portable saws, reciprocating and band saws, and routing and shearing equipment. No cutting lubricants, oils or coolants are required with any of these cutting operations.

French Designers Create Minimalistic Coffee Table With Dibond ACM

When an architect and a designer teamed up to create furniture, the ultimate modern coffee table design was created. “Table 4x4” is a culmination of P. Guillou’s skills in furniture making and J. Barrès’ skills in space design.

Scandinavian Manufacturer Creates Promotional Clocks Using Dibond

ZÜND is a Scandinavian manufacturer of digital cutting solutions. In 2013 the company created a series of Dibond, veneer and acrylic clocks.

Using an application seen mostly in art galleries, ZÜND combined Dibond and acrylic to create an impressive look.

Italian Design Firm Creates Lamp From Single Sheet of Dibond ACM

Italian firm-ZPSTUDIO has focused on commercial, corporate, product and architectural design since 2003. Their creation of an iconic table lamp, Zeta, is part of their ZPSTUDIO TOOLS collection that features small-scale Italian production and craftsmanship. The ZPSTUDIO TOOLS collection embodies a unique relationship between traditional Tuscan crafting techniques with materials used in industrial production.

Dibond Used In Unique Motorcycle Design by Automotive Engineer

The original “Norton Shrike” road bike was designed and built in 1983 as a safer alternative to the conventional motorcycle. It’s creator, Dave Norton, has over two decades of automotive racing and engineering experience.

Brooklyn Design Firm Creates Nike Athletic Case Using Dibond ACM

Project Name: Nike Football Cold Weather Case

Project Location: Brooklyn, New York

Date of Completion: 2011

Designer: WeShouldDoItAll (WSDIA)

Fabricator: The Guild

Creative Direction: Kevin Wolahan, Nike

Project Management: Julie Kenney, Fluid

Post-Production Photography: Portus Imaging

The designers at Brooklyn-based firm WeShouldDoItAll (WSDIA) were tasked by Nike with the extraordinary job of designing a case for NFL pro athletes in two days.

Dibond Aluminum Composite Panels Create Storage As Bicycle Racks

Taking his love of bicycles, coupled with his desire to build and problem-solve, Joseph Ahearne became a custom bike framer in Portland, Oregon. He uses bike design as a form of creative expression as well as a method of promoting environmental awareness.