Gatorfoam needs no special preparation before priming or painting. The surface should be clean and free of any oil or contaminates. If the surface has become lightly soiled or scratched, it may be hand sanded with silicon carbide dry paper 180 grit or finer. After sanding, be sure to clean surface well to remove any dust particles. For optimum results, the surface should be sealed with a good primer.

Gatorfoam can be painted with acrylic base enamels (water base or oil base), or oil base lacquers (solvent base). Caution should be exercised when using oil base or solvent base systems to prevent contact with the polystyrene foam. These types of paints are likely to attack and deteriorate the foam core.

Any of the common methods application (spray, roller or brush) may be used.

Spray coating normally offers the best all-around results with smoother, more uniform coverage. Curtain coating is not recommended due to a bubbling action created in the paint. The bubbling is caused by an air displacement and solvent flashing situation when applying a high volume of paint so quickly. This problem may be minimized by specifying flat pigment and slower solvents in the paint or by using water base paints. The paint system may vary depending on the individual requirement or desirability.

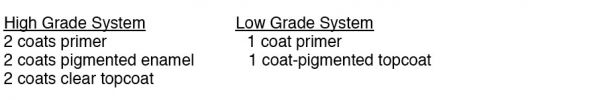

There are currently a wide range of systems in use. These include:

In cases where the foam edges might be subjected to exterior exposure, it is necessary to protect the edges from deterioration by the high intensity ultra-violet light from the sun. It is necessary to protect to foam edge if it is exposed to UV radiation from the sun to keep them from deteriorating. A good coating of a pigmented water-base paint or similar UV barrier should be sufficient to provide this protection. Care should be taken if dark colors are used to coat the edge of the foam since they sometimes do not have a sufficient amount of UV inhibiting pigment in their formulations. With dark colors it may be necessary to use an undercoating that has a heavy load of UV inhibiting pigment or a good quality UV overcoat to achieve adequate UV protection. For exterior applications the edges must be inspected and touched up as necessary.

Drying by oxidation and evaporation is preferred. When it is possible, allow the freshly painted Gatorfoam to dry the length of time suggested by the particular paint manufacturer.

Featured artwork courtesy © of Donna Shortt, painted Gatorfoam with gesso and pumice powder, oil paint then pastels.