How a Fine Art Photographer Found the Ideal Substrate in GATORFOAM®

Installation view of Cruise Control by Charlie Tadlock – Photos Courtesy of the Artist

For his master's thesis exhibition "Cruise Control," fine art photographer Charlie Tadlock sought a solution for evenly mounting several large-scale, 40”x 80” prints. His vision—to create a non-linear narrative mirroring the chaotic and intricate nature of American West highways—called for an unconventional display method. The project required a substrate that was not only large enough to handle the prints' proportions but also possessed the specific properties to ensure his vision was realized.

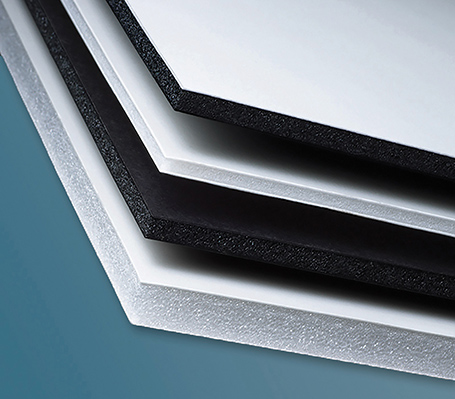

Tadlock found his solution in GATORFOAM, a uniquely differentiated foam board that offered the strength and stability he needed. "I initially experimented with standard, paper-lined foam board with a black core but determined that at the scale for which it would be used, it would not be rigid or stable enough to deliver a flat appearance," Tadlock explained.

The Challenges of a Non-Traditional Exhibition

The exhibition's design called for large-scale prints to be hung constellation style, paired with smaller, framed photographs. The goal was to create a multi-dimensional display that would highlight the complex relationship between the images. This approach presented several technical challenges:

Uneven Walls: The exhibition space was an old building with walls that were not level and boasted prominent vertical seams. This meant the prints would be mounted to a media that could maintain a perfectly flat surface despite the irregularities of the aging structure.

Aesthetic Requirements: The mounted prints had to look as if they were nearly flush with the wall, creating an illusion of a floating display. This demanded a thin but incredibly rigid substrate.

Mounting and Installation: With prints measuring 40 x 80 inches, it was necessary for the material to be lightweight enough for easy handling and installation by a small team.

Custom Fabrication: The project's aesthetic stipulated that Tadlock be able to cut the material with a 45-degree back-bevel, allowing him to conceal the substrate.

A Clear Winner: The Superiority of GATORFOAM

Before settling on GATORFOAM, Tadlock considered several other options, including vinyl, standard paper-lined foam board and styrene sheets. Vinyl was aesthetically unacceptable due to its low print quality and inability to compensate for the wall's unevenness. Other foam boards lacked the necessary rigidity and durability for the large format, while styrene and other substrates traditionally used for signage were too heavy and difficult to work with using simple tools.

Tadlock said, "After considering cost, accessibility, thickness, strength and the ability to cut and shape it with simple shop tools, GATORFOAM was a clear winner. Its 3/16-inch gauge proved to be the perfect balance of lightness, durability and rigidity, allowing the prints to maintain their shape and integrity despite the uneven wall surface."

Seamless Mounting and Fabrication

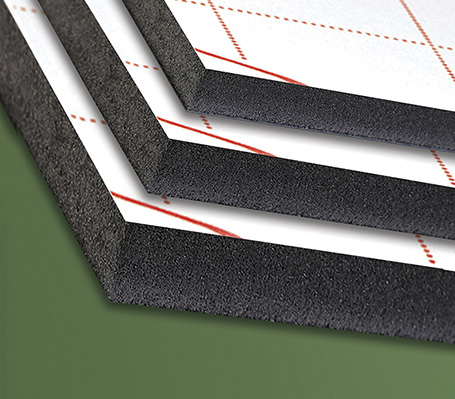

To ensure flawless mounting, one of Tadlock’s most significant decisions was using the self-adhesive GATORFOAM. Doing so eliminated the messy and challenging process of evenly applying a distinct adhesive to the large prints. Describing the ready-to-use surface, Tadlock noted, "The adhesive was incredibly even and consistent in its application, calling for only minimal pressure to achieve complete adhesion. This characteristic was crucial for ensuring a bubble-free, flawless finish.”

The board's extraordinary rigidity also made the fabrication process simple and clean. Using a table saw with a high tooth count blade, Tadlock was able to cut the large sheets down to size and create a precise 45-degree back-bevel. "The foam edges were very nice when cut," he said. "There was no tear out on the adhesive side which was fantastic since that was the 'good side' and most likely to be visible."

For installation, Tadlock devised an ingenious, concealed mounting system. By leaving a 6-inch border of the adhesive liner on the edges of the board, he was able to drill and counterbore screw holes. The prints were then adhered over the screws, concealing the hardware and maintaining the sleek, flush-mount appearance. "The board never gave me any surprises, it consistently outperformed my expectations, and was really easy to work with," he stated.

Charlie Tadlock's “Cruise Control” demonstrates how the unique properties of the self-adhesive GATORFORM, with its strength-to-weight ratio and exceptional rigidity, made it the ideal choice for a demanding fine art application. The product's performance and ease of use allowed the artist to focus on his creative vision, resulting in a stunning and successful exhibition.

Order samples of GATORFOAM Self-Adhesive today!

View more work by Charlie Tadlock - https://www.charlietadlock.com/installation

Articles by Product: [ERRWPI1212]

FOME-COR® SIRIUS, DISPA® SIRIUS with ColorPRO Technology Introduced for Enhanced Digital Print Performance

FOME-COR® SIRIUS and DISPA® SIRIUS – the first and exclusive graphic display boards to feature HP ColorPRO Technology – were developed through a multi-year collaboration between 3A Composites and HP to enable printing system performance that delivers color excellence in digital printing.

ACI Design Finds Limitless Possibilities When Creating Office Decor for 3A Composites USA with Company’s Rigid Substrates

DAVIDSON, N.C. (May 24) – When the longest-operating U.S. graphic display board manufacturer with the widest offering of rigid substrates engages a design and production firm to showcase the company’s well-known product lines, creative applications are limitless.

New FOME-COR® Collection Offers Widest Portfolio Of High-Quality, Innovative Foam Boards For Displays, Graphic Arts, Framing

3A Composites USA is pleased to announce its newly integrated FOME-COR® Collection – the widest portfolio of high-quality, innovative foam boards designed to meet the needs of the display, graphic arts and framing industries.

Introduction of this newly integrated FOME-COR Collection follows 3A Composites’ recent acquisition of the EnCore® Products and Elmer’s® foam boards division from Atlanta-based Newell Brands, Inc.

New JIB Box Protects Packages From Porch Pirates, Weather Damage With Durable SINTRA® PVC Board

While the popularity of on-line shopping has been increasing steadily for the past several years, e-commerce has experienced exponential growth during the COVID-19 pandemic as a safe, convenient alternative to the in-store retail experience. Adobe has reported that total online spending in May 2020 was up 77 percent year-over-year and has projected a 33 percent year-over-year increase in 2020 holiday online spending.

The Next New: Retail’s Reaction to A Hectic 2020 Holiday Season

This holiday spending season is bound to be unlike any our industry has ever witnessed. Retailers have been forced to react and create new in-store models while shoppers have completely altered their approach to buying. The effects of COVID-19 on Retail, QSR and Fast Casual have resulted in a permanent evolution of the in-store experience.

New GATORFOAM® SELF-ADHESIVE Introduced As Easy Mounting Solution By 3A Composites USA

New GATORFOAM® SELF-ADHESIVE graphic display board has been introduced by 3A Composites USA as an easy mounting solution for projects that require the extreme rigidity, strength and durability offered by this high-performance rigid substrate.

Sculptor’s Lifelike I-Beam Mobiles Float Near Weightlessly with SINTRA® Graphic Display Board

Sculpted to resemble the massive and heavy structural steel girders used to construct skyscrapers, the I-beam mobiles of J F Jones instead are designed to float near weightlessly above the viewer and to produce a smile with 3-D characters casually perched atop the beams.

Architects Rejuvenate Cultural Services Center by Upcycling 200 DIBOND® Panels In Creative Installation

© Andrea Zanchi

The Centro Servizi Culturali Santa Chiara is a cultural services center situated in the northern mountains of Italy, in the province of Trento. The Center offers cultural arts events to the public, such as musical and theatrical performances, and historical installations as well as meeting and event spaces. Along with the Center's two theaters, an adjoining urban park links different parts of the city attracting people of all ages and cultures. Unfortunately, part of the Centro Servizi has been uninhabited for ages and in a severe state of disrepair despite the fact that it is partially protected by "Sovrintendenza dei Beni architettonici", a cultural heritage committee. Except for graffiti of a modest artistic level, there are offensive and xenophobic writings on the walls, evidence not only of urban but also civil decay.

Local architects Elisa Burnazzi and Davide Feltrin, co-owners of Burnazzi Feltrin Architetti, have rejuvenated the entry way to the Centro Servizi by upcycling approximately 200 DIBOND® panels recovered from billboards used to advertise past performances at the Centro Servizi.

Nationally Recognized Craft Brewery Tour Enhanced with Story-Telling DIBOND® Decor

Photos courtesy of Agio Imaging

Bell’s Brewery, Inc., a regional brewer headquartered in Kalamazoo, Mich., has been making a name for itself since 1985 by brewing quality craft beers in both its Kalamazoo and Comstock, Mich., locations.

While started as a quest by Larry Bell, president

of Bell’s Brewery, to create a better beer in a 15-gallon stovetop soup kettle,

this independent, family-owned business is now the seventh largest craft

brewery in the United States, brewing more than 20 craft beers for distribution

by Bell’s Brewery employees throughout 41 states as well as in Puerto Rico and

Washington, D.C.